Decaf Coffee Processes

What makes a coffee decaf?

What does decaf actually mean? Does it mean that there is absolutely no caffeine left in the coffee? Not quite - technically speaking, decaf coffee has between 95% and 98% of the caffeine removed (with the FDA requiring at least 97%). This means nearly all decaf coffee still has a bit of caffeine left in it, but far less than any standard coffee. Part of the reason of this variance is how the caffeine is removed in the first place, before the coffee is roasted.

A similarity in decaffeinated coffee across the board is how the green coffee beans are prepped for decaffeination. This takes place by the raw coffee being steamed or soaked for a long enough time that the pores of the coffee open up, and allow for the caffeine to be later removed. The actual technique for how the caffeine is then removed and what materials are used is where things become different.

So, what are the popular methods of removing caffeine?

Ethyl Acetate

Ethyl Acetate - sometimes referred to as “Natural Process” is one of the most popular ways to remove caffeine from green coffee. Ethyl Acetate is a naturally occurring byproduct of fermented sugars, and is used as a solvent to bond with caffeine in the coffee bean. To remove the caffeine, the coffee is steamed to open the pores of the bean, then placed in a tank with ethyl acetate and water. The caffeine and small amounts of other compounds bond with the ethyl acetate, the tank is drained, and then refilled. This step will be repeated as many times as necessary to remove as much caffeine as possible.

Once the caffeine is removed, the beans are then steamed again to remove any traces of the ethyl acetate on the coffee. Finally, the beans are then dried, and polished before exporting.

From Cafe Imports

Water Process

Water processes are methods in which only water is used to separate the caffeine from the coffee. There are two big players in this process being Swiss Water Process (SWP) and Mountain Water Process (MWP) - these both use very similar methods to decaffeinate the coffee, and mainly vary on where the processing plant is geographically located (Switzerland and Mexico, respectively).

For these, water is used to pull out all compounds of the coffee - both flavor and caffeine. This compound loaded water is then filtered through carbon filters enough times that only the caffeine is removed from the water - leaving behind the flavor compounds. The water is then reintroduced to fresh green coffee, where the caffeine molecules are drawn out of the coffee and into the compound saturated water through continual circulation and filtration to remove caffeine from the water over the course of several hours. This is done until the caffeine content in the beans has reached 0.1% or less. Lastly, the beans are dried and prepared for shipment.

From Swiss Water Process

Methylene Chloride

This process used methylene chloride as a solvent to bond with the caffeine molecules separated from the green coffee throughout the processing. There is some variance in exactly how the methylene chloride is added to the coffee, but generally steam and hot water are used to draw out the compounds of the coffee, caffeine being the target. Methylene chloride is then added to either the beans directly, or to compound loaded water after the beans have soaked, and bonds directly with the caffeine molecules to remove it from the beans/water.

Any residual methylene chloride is then removed with steam from the coffee, and left to dry, leaving less than 1 part per million by the time the coffee is roasted and brewed. Caffeine content removed lands somewhere between 96% and 97%.

Our Thoughts on Decaf

Decaf coffee is a great way to allow folks to enjoy not only the taste of coffee, but the sense of community and joy that sharing a cup with other people creates without worrying about the time of day or caffeine intolerances. When choosing decaf coffees, we value the amount of origin characteristics that are present in the beans to showcase all of the hard work that growers had done to bring that coffee to our cups. Environmental impact is another point of consideration for us, ensuring that the processes used for our decaf coffee produces as little waste as possible and minimizes any negative impacts.

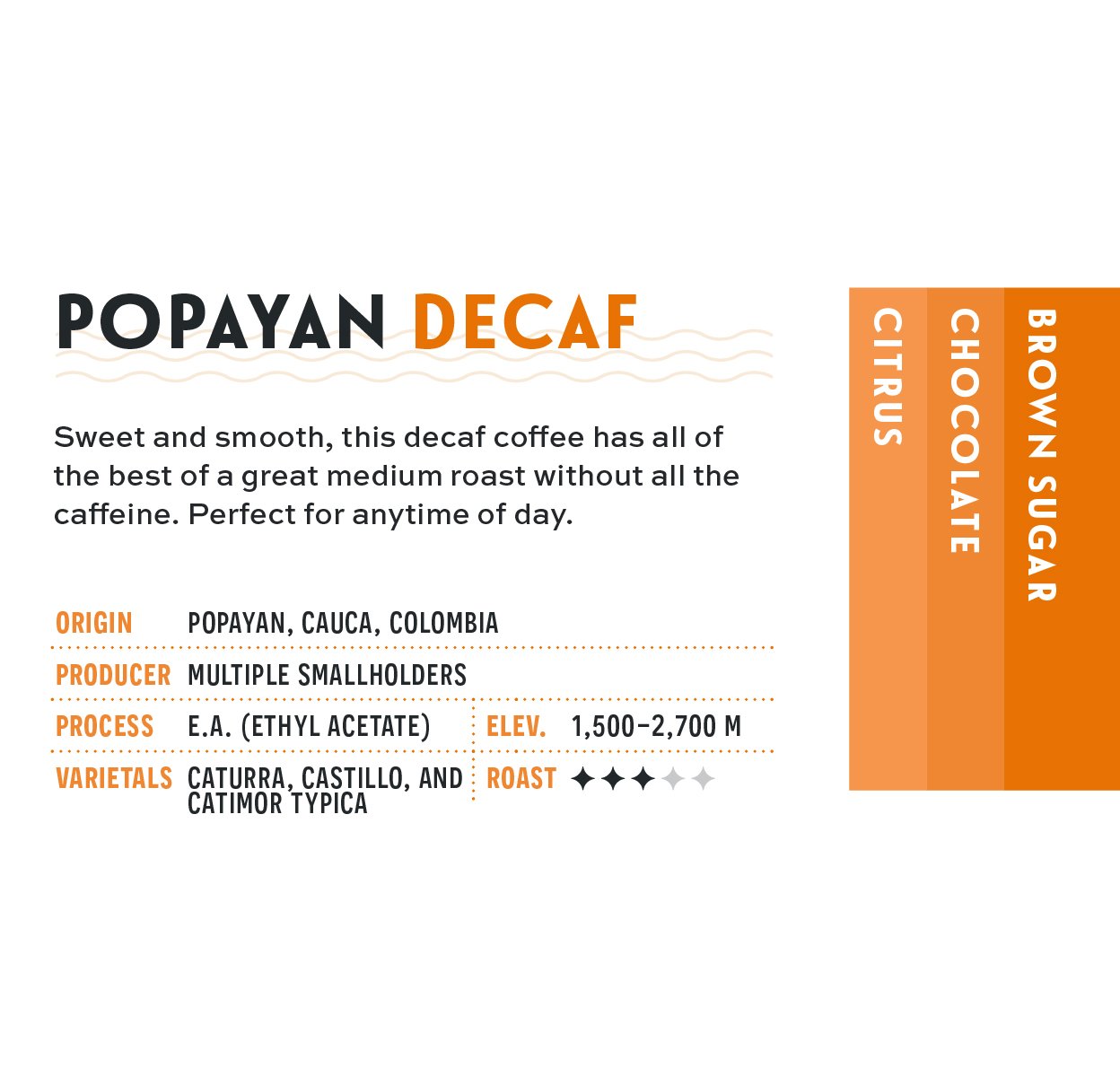

Our current decaf offering uses the Ethyl Acetate process, one of the benefits being the minimized amount of flavor compounds that are removed from the green coffee - leaving the coffee full of it’s origin flavor characteristics with a taste profile very similar to a caffeinated coffee.

Have questions about decaf coffee? Want to chat about different processing methods, or how decaf can affect how we roast it? Reach out to us at talk@defer.coffee to continue the conversation!